Facts

- Capacity in Temse: 26,000 m³ of concrete a year

- Capacity in Hoeselt: 5,000 m³ of concrete a year

- Conveyor capacity: 700 tonnes an hour

- Steel capacity: 18,000 tonnes a year

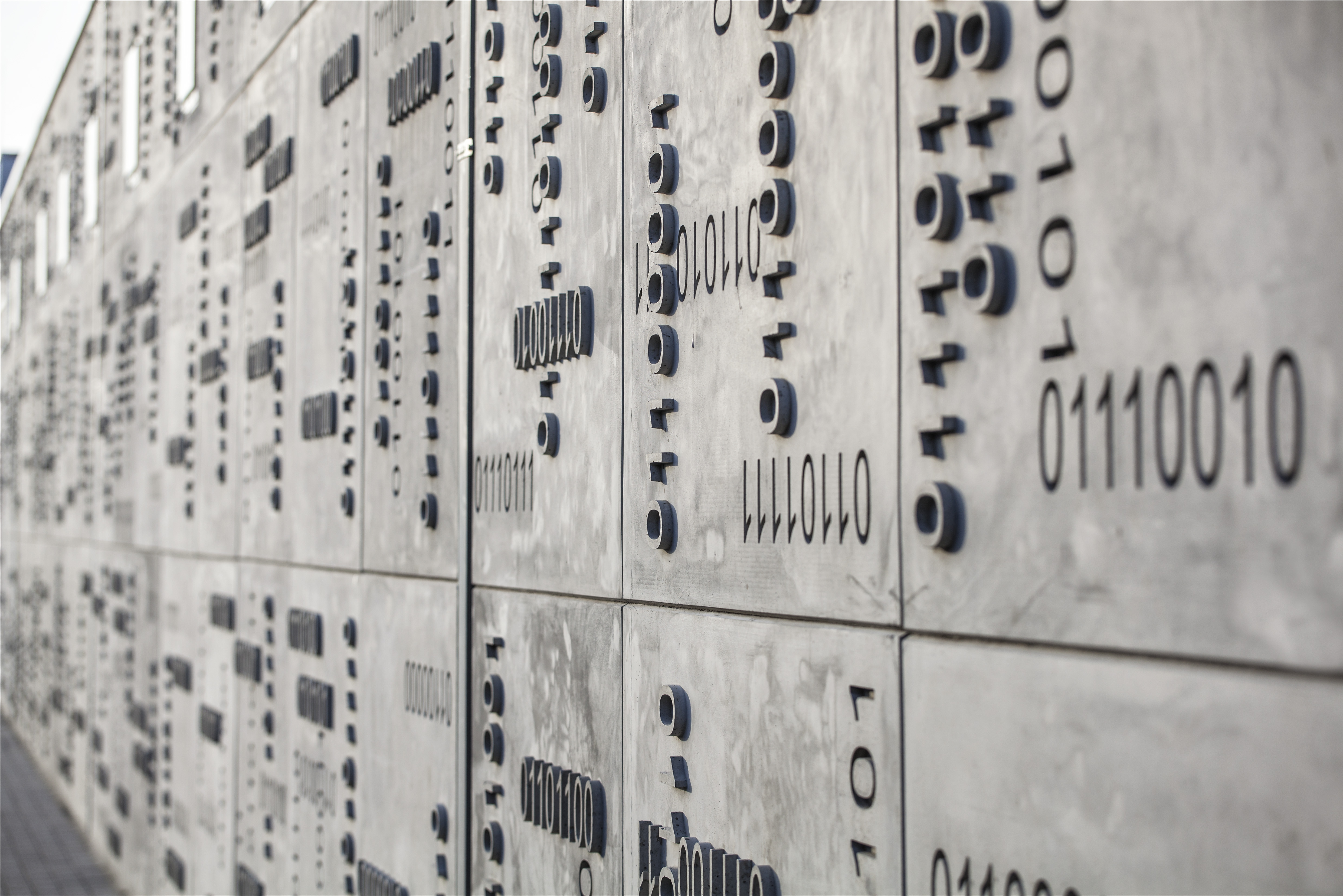

Our two concrete factories have a capacity of up to 35,000 m³ a year. Each factory includes its own concrete mixing plant, a double wall carousel plant, an automatic reinforcing wire mesh machine, a laboratory for permanent quality control and an exposed concrete department. A wide range of prefab elements are manufactured on site, including columns, beams, wells, straight stairs, spiral staircases, balconies and wall units. This allows our professionals to respond quickly to clients’ demands while meeting the highest quality standards. Quality is guaranteed!

The C-fast system was developed at the end of the 1970s as a demountable building system. For the school buildings sector, C-fast was the first modular building system on the prefab concrete market. The beamless system has since then evolved into an all-round modular product which makes it possible – through smart connections – to assemble, disassemble and extend the elements rapidly, both vertically and horizontally.

Main advantages:

Efficient construction

Interested in learning more about the possibilities of prefabricated concrete? Sander Dekker and Adri de Rijke would be delighted to tell you about the benefits.